The major thrust of the division is to manage the genetic resources in coconut, arecanut and cocoa for breeding the high-yielding varieties/hybrids with resistance to biotic and... Read More>>

About Us

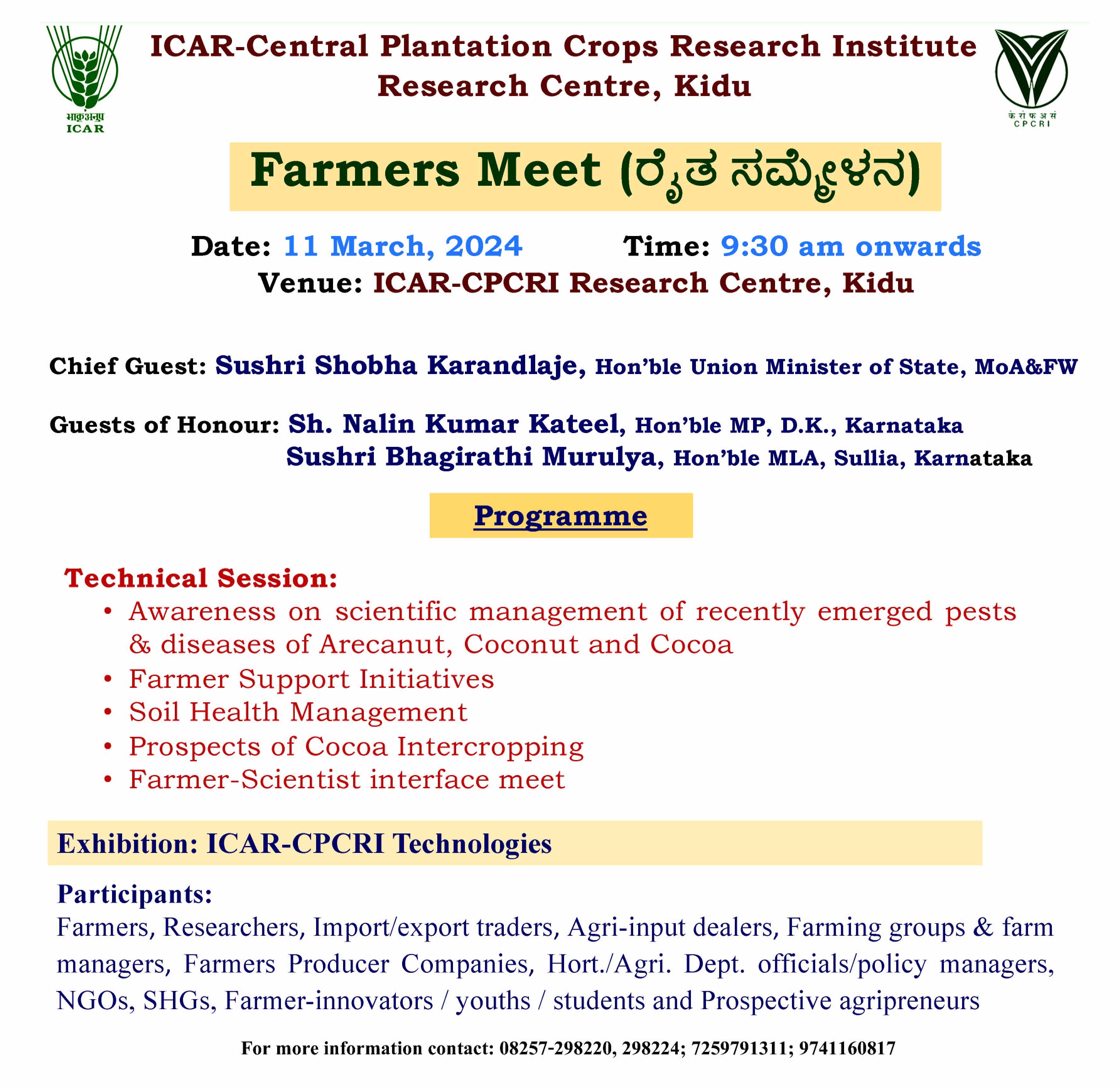

The Central Plantation Crops Research Institute (CPCRI) was established in 1916 as Central Coconut Research Station, and was later taken over by the Indian Council of Agricultural Research (ICAR). The ICAR established CPCRI in 1970 by merging Central Coconut Research Stations... Read More >>